EFFECTS OF DRILLING METHODS ON TENSILE CAPACITY OF MECHANICAL SCREW ANCHORS IN MASONRY WALLS

in 18th world conference on earthquake engineering, Milan

Scope and methodology

Standard anchor installation procedures involve heavy hammer drilling, suitable for hard materials such as modern reinforced concrete. Existing masonry buildings commonly consist of soft and, on occasion, brittle materials.

The comprehensive investigation encompassed three key stages: quantification of substrate damage from different drilling techniques, investigation of blowout and micro-cracking behavior, and quantification of micro-cracking on anchor tensile capacity.

Testing was conducted in various substrates including solid clay bricks (new and vintage), concrete masonry (CMU), and limestone using different drill bits and different drilling methods: heavy hammer, light hammer, and rotary-only.

FINDINGS

The choice of drilling method significantly influences anchor performance across all investigated masonry substrate types:

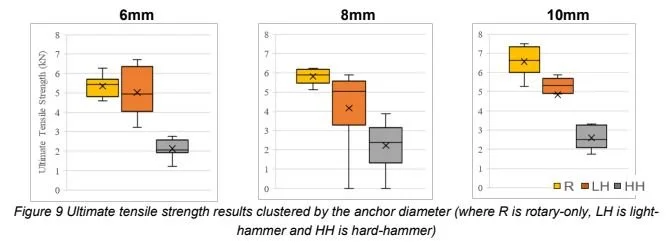

Rotary-only drilling consistently proved superior anchor performance with higher anchor pull-out capacities and reduced variability.

Heavy hammer drilling was the fastest drilling method but led to brick blowout, micro-cracking, and substantial reductions in anchor capacities by up to 62%. These results also exhibited the highest level of variability in anchor capacity.

Light hammer drilling led to intermediate anchor pull-out performance with a reduction in anchor capacity between 27% and 6%, based on the anchor diameter.

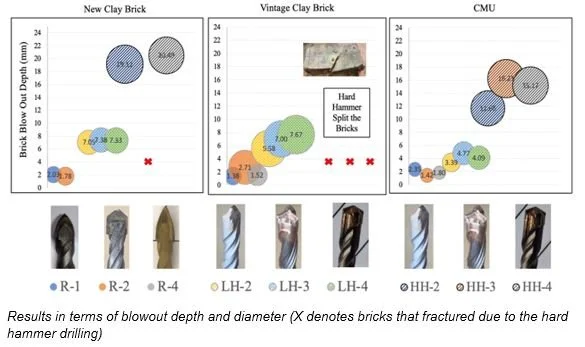

Blowout depth with heavy hammer drilling reached up to 40% of the brick thickness, in contrast to rotary-only drilling which consistently maintained a minimal blowout depth (2% to 6%) across all substrates tested.

Two-edge drill bit (rotary-only, aka PYTHON spear drill bit) emerged as the most efficient for existing masonry applications, consistently minimizing damage to the substrate (reduced blowout and micro-cracking) resulting in higher anchor capacity.